Pharmaceutical

Applications

Wet Granulation: High Shear and Fluidized Bed

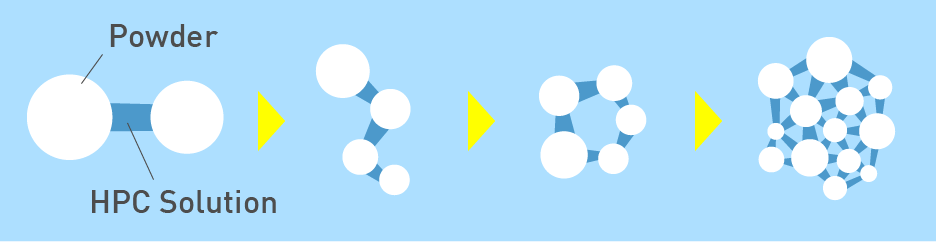

NISSO HPC can be readily dissolved in both water and most organic solvents to prepare effective granulation solution. Poor flow and compaction actives can be successfully granulated using NISSO HPC to make tableting more feasible through both high shear wet granulation and fluidized bed granulation methods.

Image of granulation using HPC as bridging polymer

Dry Granulation: Direct Compression and Roller Compaction

NISSO HPC is highly plastic and deformable, and exhibits high cohesive and adhesive forces, all important characteristics of a robust direct compression dry binder used for solid oral dosage forms. We often recommend HPC SSL-SFP for some of the most challenging direct compression formulations because of its super fine particle size, high plasticity and enhanced compressibility, allowing formulators to create tablets of outstanding quality.

NISSO HPC Grades

| NISSO HPC | SSL | SL | L | M | H | VH | |

|---|---|---|---|---|---|---|---|

| Viscosity (mPa·s) 20℃/2% aq. solution |

2.0-2.9 | 3.0-5.9 | 6.0-10.0 | 150-400 | 1000-4000 | 4001-6000 | |

| Molecular weight / GPC-RI method | 40,000 | 100,000 | 140,000 | 700,000 | 1,000,000 | 2,500,000 | |

| AVAILABILITY | Regular Powder (40 mesh pass) D50: 150-190 μm |

* * |

|

|

|

|

|

| Fine Powder (100 mesh pass) D50: 80-110 μm |

|

|

|

|

|

||

| Super Fine Powder (330 mesh pass) D50: 20 μm |

|

||||||

| APPLICATION | Direct Compression Dry Granulation

|

||||||

* Particle size of the Regular Powder: 85μm

3D Printing: Powder Flow and Fused Deposition Modeling (FDM)

NISSO HPC can be used to prepare stable amorphous solid dispersions via various techniques including FDM (Fused Deposition Modeling) and Powder Flow Method.

NISSO HPC Grades

| NISSO HPC | SSL | SL | L | M | H | VH | |

|---|---|---|---|---|---|---|---|

| Viscosity (mPa·s) 20℃/2% aq. solution |

2.0-2.9 | 3.0-5.9 | 6.0-10.0 | 150-400 | 1000-4000 | 4001-6000 | |

| Molecular weight / GPC-RI method | 40,000 | 100,000 | 140,000 | 700,000 | 1,000,000 | 2,500,000 | |

| AVAILABILITY | Regular Powder (40 mesh pass) D50: 150-190 μm |

* * |

|

|

|

|

|

| Fine Powder (100 mesh pass) D50: 80-110 μm |

|

|

|

|

|

||

| Super Fine Powder (330 mesh pass) D50: 20 μm |

|

||||||

| APPLICATION | |||||||

3D Printing

|

|||||||

* Particle size of the Regular Powder: 85μm

Wettability

HPC solution provides a high degree of wettability, which allows for the solution to spread evenly and efficiently across a surface, resulting in a higher level of fluid contact during processes such as wet granulation.

- General Information

- NISSO HPC Grades

-

Applications

-

Applications